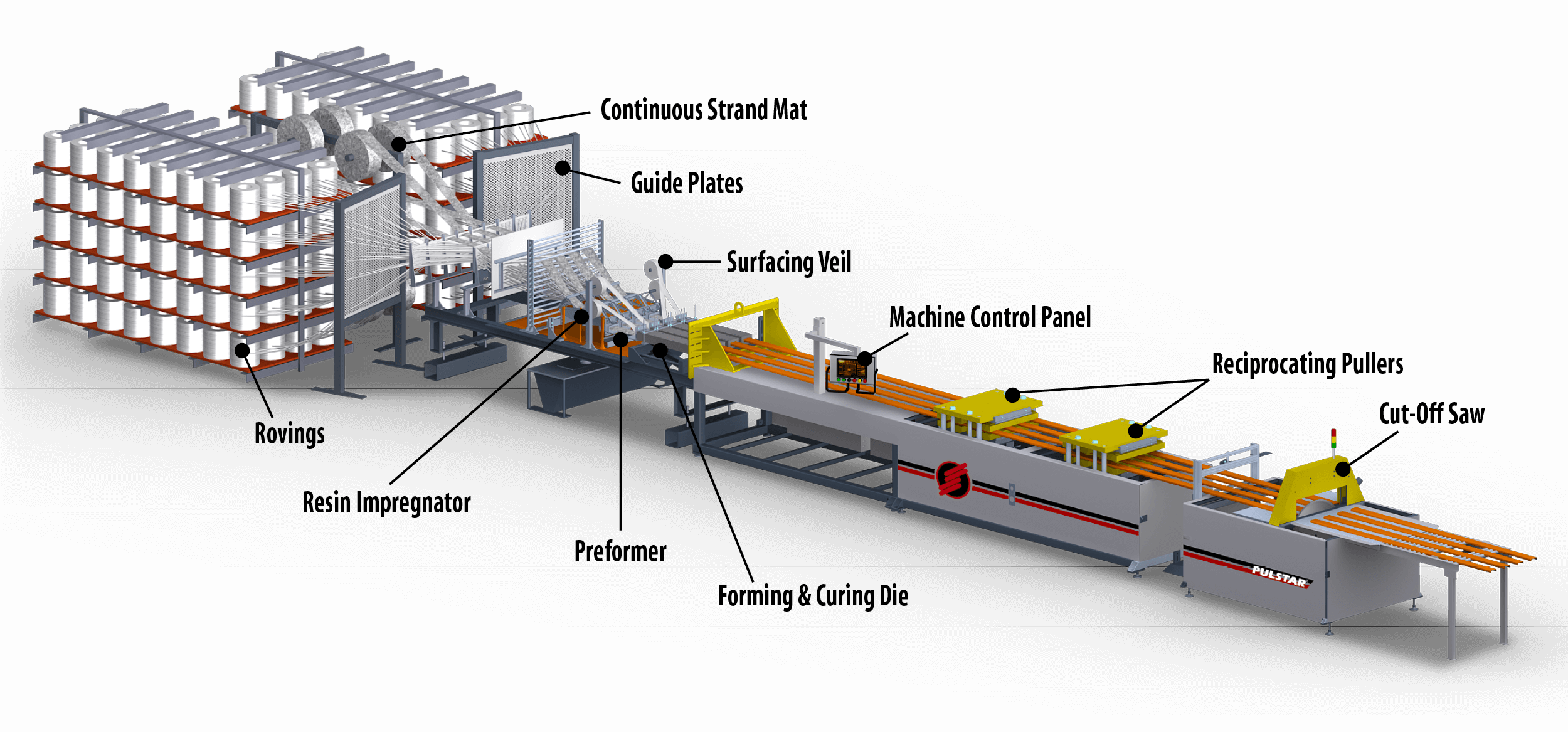

Pultrusion is a process which is analogous to the extrusion of plastics and nonferrous metals in that the profile is shaped by continuous passage of the feedstock through a forming die, but in the case of pultrusion the reinforcing fibres are used to pull the material through the die.21 Figure 6.10 shows a typical arrangement. Reinforcements of various types, but usually in a continuous form, are drawn from spools into the pultrusion die. A series of guides or bushings is generally used in front of the die to preform the reinforcement to the desired shape. Within the die, impregnation and consolidation occur as liquid resin is injected under pressure. The materials are shaped and curing is initiated as the section progresses through the heated part of the tool. The rate of throughput is controlled so that curing is essentially complete by the time the product emerges from the die. This is necessary because the material must have sufficient strength to resist the forces exerted in the traction stage. After passing through the pullers, sections are cut to the desired length.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.